What is the process flow of packaging box making and printing? Partners in the same industry know that the production of packaging boxes is a complex process. People in different industries generally think that you are asked to produce them today, and you can get them immediately tomorrow. Every other industry has its own workflow. A standard packaging is made through several processes. What is the process flow of packaging box production and printing in Shenzhen Jinyang Huayu paper products Co., Ltd? Here is a brief and specific introduction for you.

First, communicate with the customer about whether the design is needed, what kind of demand and quantity of materials to be treated, and then offer the customer a quotation. If the customer is satisfied, proceed to the next step

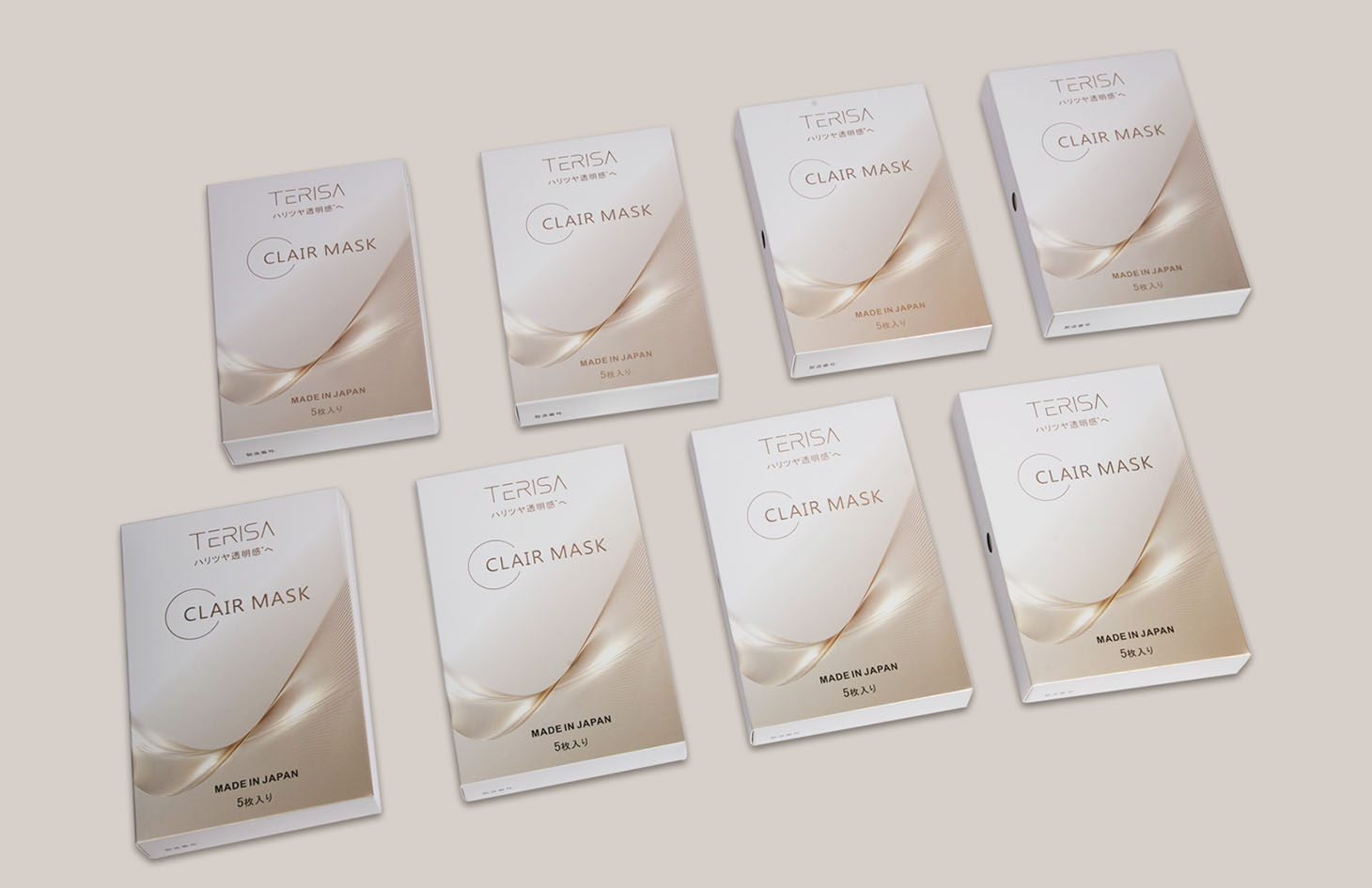

Fine gold and silver card box

Color boxes fall into two categories:

Face paper, pit paper. Commonly used paper for color box covers: grey paper, white card, coated paper, special paper, gold card, silver card, laser card, kraft paper, etc.

The subsequent processing of gold and silver cardboard boxes is generally completed by printing - surface finishing (bronzing, silver stamping, film coating, local UV, embossing, etc.) - die cutting - box pasting - Inspection - packing.

The manufacturing process of the card box is completed by printing - surface finishing - die cutting of outsourcing materials - mounting of card paper - mounting of corrugated paper - automatic box pasting machine for the bonding of the card box - Inspection - packing.

Most of the packaging materials of high-end card boxes commonly used in our daily life are paper, and the paper surface is most suitable for more process treatment. Therefore, the paper is used as the fabric

A process description.

01 paper selection

According to the customer's document design requirements and the effect to be reflected, the selection of paper is very important. Main considerations in this regard:

① Type of paper, such as gold and silver cardboard, coated paper, art paper and pearlescent paper?

② The thickness of the paper. The paper should not be too thick, which is easy to wrinkle when mounting, but it should not be too thin, otherwise the convex effect cannot be reflected.

③ Consider the decorative effect of the surface.

02 surface decoration

There are many surface decoration processes. The most common ones are (7+1) (8+1) UV printing, and then various processes based on this are:

① Reverse glazing;

② Film covering (light film, dumb film, tactile film, scratch resistant film, etc.);

③ Hot stamping (gold, red gold, color gold, silver, laser, etc.);

④ Locally scrape UV oil or screen ink;

⑤ Special colorful powder;

⑥ Convexity;

⑦ Embossing, etc.

White cardboard

Material characteristics: the white cardboard is firm, thick, white on both sides, with high stiffness, burst resistance and smoothness. The paper surface is flat. The commonly used white cardboard with a thickness of 190g-400g is used

The printed color is full and the texture is very good.

Whiteboard (gray background whiteboard)

Material characteristics: white board is a kind of paperboard with white and smooth front and gray background on the back. The commonly used thickness is 250g-400g. One side of the white board is white and the other side is gray.

Copper plate paper

Material characteristics: copper sheet paper is characterized by very smooth and flat paper surface, white on both sides, good gloss, and three-dimensional printed graphics. The commonly used thickness is 128-350 g, copper

The printing effect of master paper is the same as that of white paperboard. The color is full and bright, but the stiffness is not as good as that of white paperboard. Generally, it is mounted on paperboard or corrugated paper. The material of the color box is determined according to the shape and size of the product,

Commonly used materials are: 280g powdered paper, 300g powdered paper, 350g powdered paper, 260g powdered paper mounted on e pit, 260g double powdered paper mounted on e pit

Corrugated paper

Material characteristics: the surface is white board paper, the surface paper is stronger and thicker than the surface corrugated bottom box, and the burst resistance and pressure resistance are greatly increased, which can load products with greater weight. In addition, the corrugated box has

With a certain degree of shockproof and pressure proof function, it has stronger protection ability and can better protect new products inside.

Gold and silver cardboard

Material characteristics: Gold Silver paperboard is a kind of special paper, which is divided into two types: bright gold paperboard and dumb gold paperboard, bright silver paperboard and dumb silver paperboard; It has very high gloss, bright colors and full layers,

The light column produced on the surface has the effect of laser paper. The packing box made of the utility model has the characteristics of waterproof, corrosion resistance and abrasion resistance.

Specialty paper

Material characteristics: special paper is made of surface paste and each layer of bottom paste. Therefore, the pulp is generally divided into surface pulp (surface layer), two-layer, three-layer and four-layer. The fiber ratio of each layer of pulp is different

Similarly, the fiber ratio of each layer of pulp varies according to the quality of papermaking.

Special paper is a kind of high-grade packaging paper, printing various trademarks and packaging cartons, such as children's toys, medicines, food, cigarette boxes, toothpaste, gift boxes and other packaging.

Special paper is special compared with other paper. When printing, we must pay attention to the characteristics of special paper and print the printed matter well. We can't waste paper and cost in vain.