What is the process flow of packaging box making and printing? Partners in the same industry know that the production of packaging boxes is a complex process. People in different industries generally think that you are asked to produce them today, and you can get them immediately tomorrow. Every other industry has its own workflow. A standard packaging is made through several processes. What is the process flow of packaging box production and printing in Shenzhen Jinyang Huayu paper products Co., Ltd? Here is a brief and specific introduction for you.

First, communicate with the customer about whether the design is needed, what kind of demand and quantity of materials to be treated, and then offer the customer a quotation. If the customer is satisfied, proceed to the next step

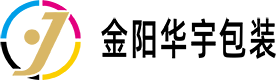

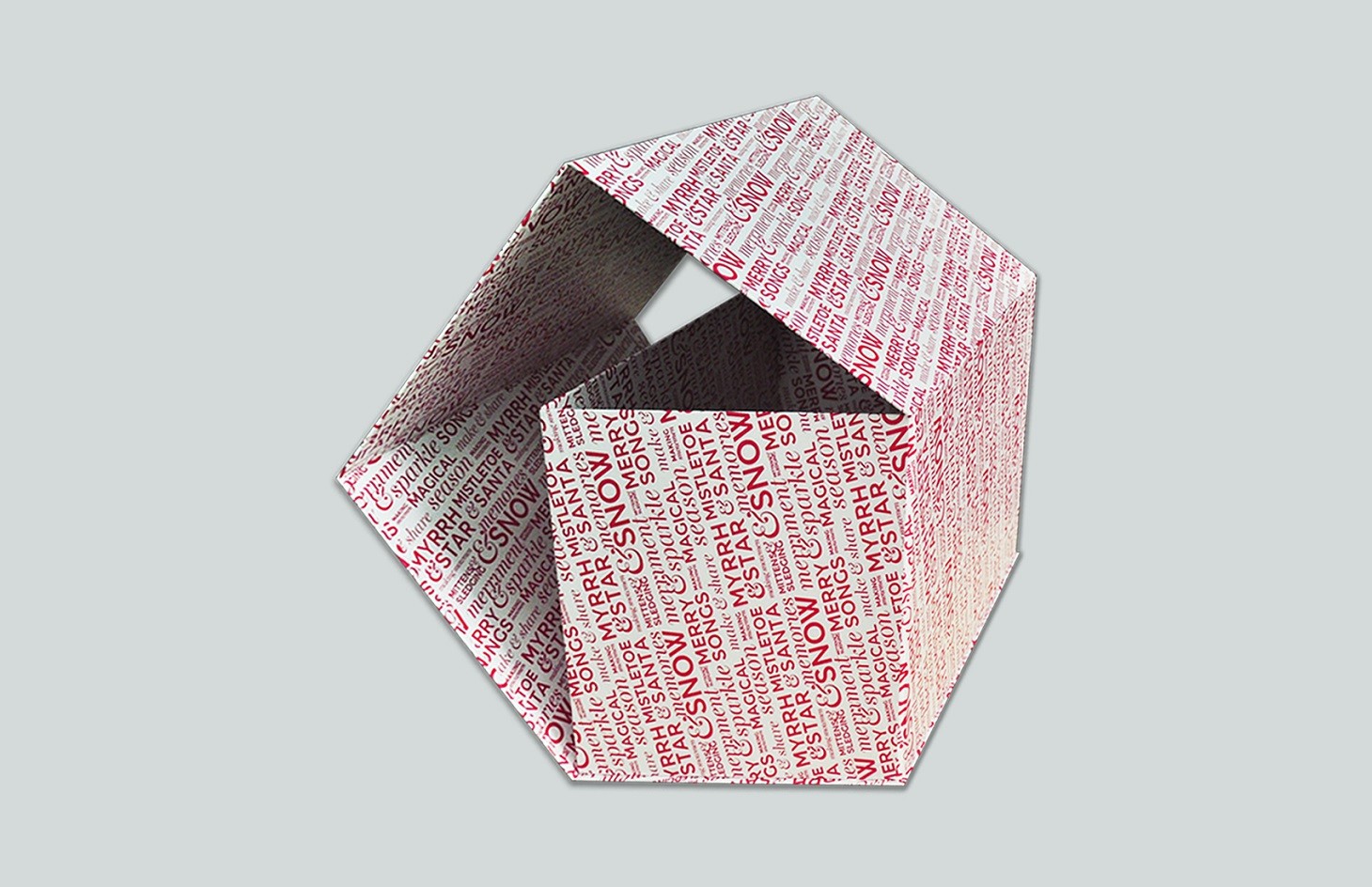

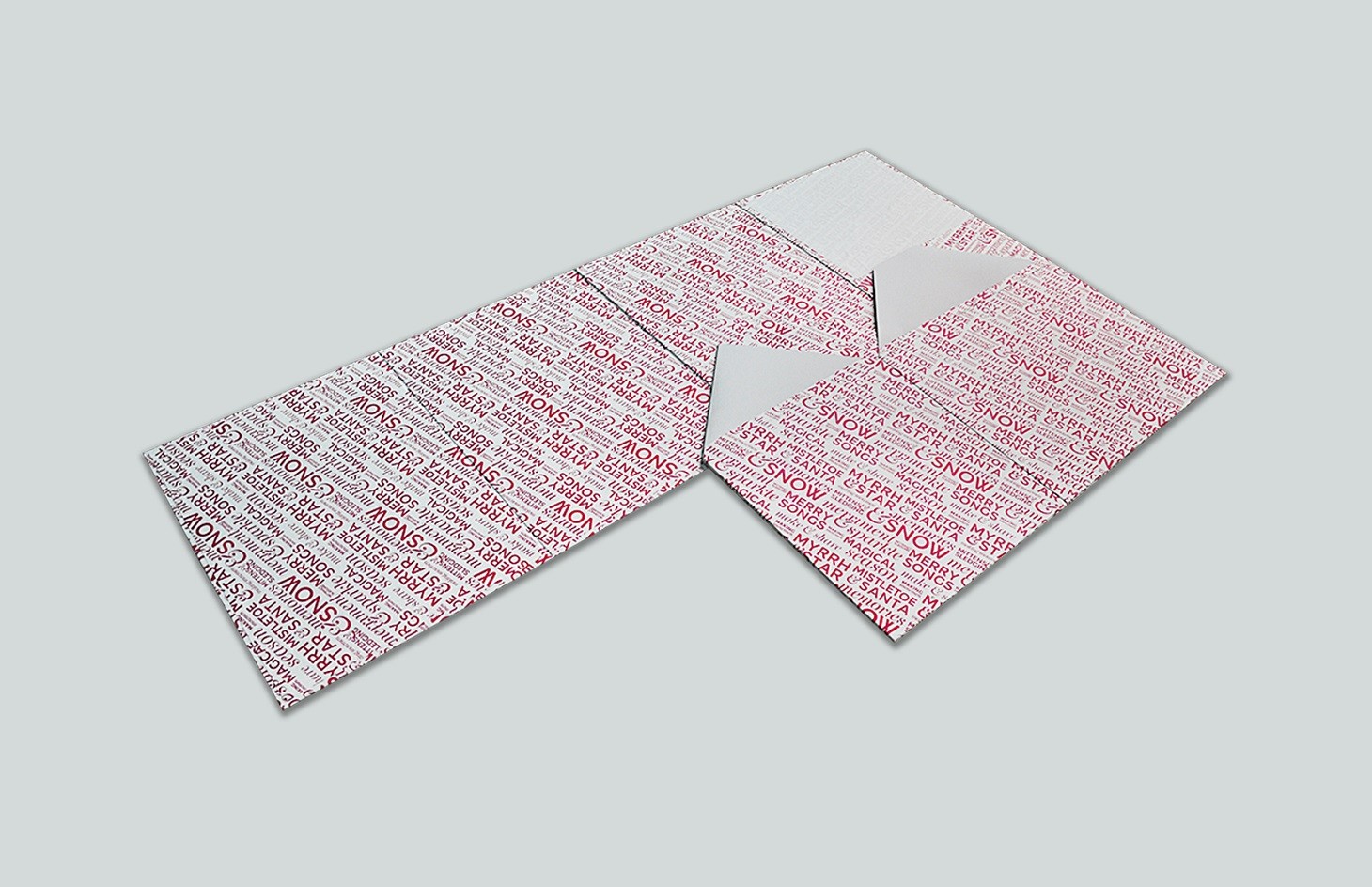

Flip fold single pink paperboard book type gift box

The manufacturing process of high-grade gold and silver cardboard gift boxes is much more complicated than that of ordinary packaging boxes. The subsequent processing of ordinary packaging boxes is generally completed by printing - surface finishing (bronzing, silver stamping, film coating, local UV, embossing, etc.) - die cutting - box pasting - Inspection - packing.

The production process of the gift box is completed by printing - surface finishing - outsourcing material die cutting - gray board die cutting - gray board slotting - gray board forming - outsourcing material pasting - assembly - Inspection - packing. From the process of the two products, the manufacturing process of the gift box is complex and cumbersome, and the process standard is much higher than that of the ordinary packaging box.

Most of the high-end gift boxes commonly used in our daily life are made of paper, and the paper surface is most suitable for more process treatment. Therefore, the following is a process description using paper as the fabric.

01 paper selection

According to the customer's document design requirements and the effect to be reflected, the selection of paper is very important. Main considerations in this regard:

① Type of paper, such as gold and silver cardboard, coated paper, art paper and pearlescent paper?

② The thickness of the paper. The paper should not be too thick, which is easy to wrinkle when mounting, but it should not be too thin, otherwise the convex effect cannot be reflected.

③ Consider the decorative effect of the surface.

02 surface decoration

There are many surface decoration processes. The most common ones are (7+1) (8+1) UV printing, and then various processes based on this are:

① Reverse glazing;

② Film covering (light film, dumb film, tactile film, scratch resistant film, etc.);

③ Locally scrape UV oil or screen ink;

④ Special colorful powder;

⑤ Convexity;

⑥ Embossing, etc.

03 selection of grey paperboard

Grey paperboard, abbreviated as grey paperboard, is produced from a kind of recycled waste paper. It is mainly divided into single grey, double grey, full grey and high gloss, which are determined according to the customer's requirements for surface flatness. It is an environment-friendly packaging material, with a ration of 250g ~ 10000g and a thickness of 0.4mm ~ 20mm. There is even no upper limit on the thickness and ration. Gray cards of appropriate specifications are usually selected according to the size of the gift box.

04 die cutting

Die cutting is a very important link in the manufacturing process. Especially for gift boxes, the technical requirements for die cutting are higher. Precision and accuracy determine the quality of products. A little error directly affects the quality of subsequent processing.

05 slotting

Slotting is to use a slotting machine to open a V-shaped groove on a 1~4mm thick gray plate. Generally, a connecting layer of about 0.25mm is reserved. The V-shaped groove is angled, generally 90 degrees or 120 degrees, or V-shaped grooves with different angles are opened according to the product structure. Slotting is a key step in the production of gift boxes. Before the gray board card is formed, the gray board must be V-shaped removed, so that after the gray board card is bent, the outside is straight and the inside is square, the edges and corners are clear, and the four corners are accurate.

06 pasting

Mounting is a necessary process in the gift box process. According to the requirements of different products, copper paper, art paper, flannelette and leather materials are glued or sprayed through the gluing machine to closely stick them together with the gray board, so as to make the gray surface of the gray board look new, which not only beautifies the appearance of the box, but also improves the added value of the packaging box.

Usually, the packaging box is mounted first and then die-cut. However, the papered gift box is mounted first and then die-cut. The purpose of this is: first, it is afraid that the outsourcing material will be stained and affect the appearance; Second, the gift box pays attention to the harmony of the overall effect, so that the back mounting can completely cover the support body, so that the gray of the gray board is wrapped by the newly designed wrapping material, presenting us with a beautiful work of art; Third, some box types with complex structures still cannot be separated from manual mounting. This is not that machines cannot replace them, but that every detail of the box can be mounted and stuck in place manually, so that the external paper mounting and gray board can be adhered more closely.